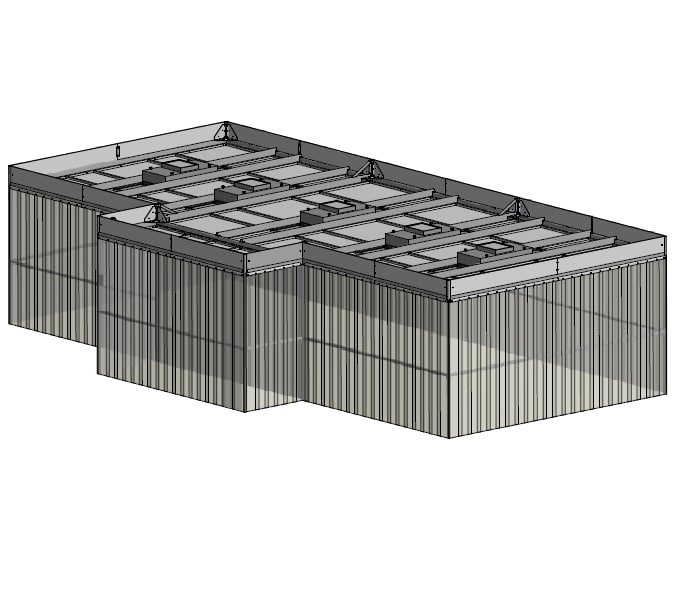

Softwall Cleanroom

What is Softwall cleanroom?

A soft wall cleanroom is a type of cleanroom that features flexible and lightweight walls, often made of curtains or flexible panels, to create a controlled environment. Unlike rigid walls found in traditional cleanrooms, soft wall cleanrooms offer versatility, easy installation, and cost-effectiveness, making them suitable for various applications.

Here are some key characteristics and components of a soft wall cleanroom:

Flexible walls: Soft wall cleanrooms typically utilize curtains or flexible panels made of materials such as vinyl, PVC, or anti-static fabrics. These walls can be easily installed, reconfigured, or removed to modify the cleanroom’s layout or accommodate different processes or equipment.

Frame system: Soft wall cleanrooms employ a frame system to support and suspend the flexible walls. The frame is usually made of lightweight materials like aluminum or stainless steel, allowing for easy assembly and adjustments.

Air filtration and HVAC: Soft wall cleanrooms incorporate air filtration and HVAC (heating, ventilation, and air conditioning) systems to maintain the desired cleanliness levels and control environmental factors like temperature, humidity, and air circulation. These systems typically include filters, fans, ducting, and vents.

Entry systems: Soft wall cleanrooms may feature various entry systems to prevent contaminants from entering the controlled environment. These can include strip doors, air showers, or pass-through chambers that allow personnel or equipment to enter while minimizing the introduction of particles.

Lighting: Soft wall cleanrooms are equipped with appropriate lighting systems, often using cleanroom-grade LED lights. These lights are designed to minimize particle generation and meet the required illumination levels for the specific cleanroom application.

Advantages of Softwall cleanroom

Soft wall cleanrooms are commonly used in industries such as electronics manufacturing, pharmaceuticals, biotechnology, research laboratories, and food processing, where a controlled environment is needed but without the need for rigid walls. They offer several advantages, including:

Flexibility: Soft wall cleanrooms can be easily adjusted, reconfigured, or expanded as per changing needs or facility requirements.

Easy installation: Compared to traditional cleanrooms, soft wall cleanrooms are quick to install, minimizing downtime and disruptions to ongoing operations.

Cost-effective: Soft wall cleanrooms are generally more affordable than rigid wall cleanrooms, making them a cost-effective option for many businesses.

Versatility: The flexible walls of soft wall cleanrooms allow for easier integration with existing structures or equipment, accommodating specific workflow or space constraints.

However, it’s important to note that soft wall cleanrooms may not provide the same level of cleanliness or control as rigid wall cleanrooms. The choice between soft wall and rigid wall cleanrooms depends on the specific requirements of the application and the desired level of environmental control.

Comparison

Each type of cleanroom has its advantages and suitability depending on specific requirements, such as the desired level of cleanliness, flexibility, customization needs, budget, and project timeline. Choosing the right type of cleanroom involves considering these factors and assessing which option aligns best with your specific needs.

Construction | Flexibility | Installation | Cost | |

Modular Cleanroom | Modular cleanrooms are pre-engineered, prefabricated structures that consist of individual components or modules. These modules are manufactured off-site and assembled on-site. | They offer high flexibility and can be easily modified, expanded, or relocated according to changing needs. | Installation: Modular cleanrooms have a faster installation time compared to stick-built cleanrooms since they involve assembling pre-made components. | Cost: They tend to be more expensive initially due to the prefabrication and modular components, but they offer long-term cost savings due to their flexibility and reusability. |

Stick-Built Cleanroom | Stick-built cleanrooms are constructed on-site using traditional construction methods. They involve building the structure from scratch, including walls, ceilings, and floors. | They offer high customization options, allowing for precise design and integration with existing facilities or specific requirements. | Stick-built cleanrooms typically have a longer construction time compared to modular cleanrooms as they require on-site construction and coordination with various trades. | Cost: Initially, stick-built cleanrooms can be more cost-effective for small-scale projects, but they may involve higher costs for customization and modifications. |

Soft wall Cleanroom | Soft-wall cleanrooms are constructed using flexible materials like vinyl curtains or panels. They are typically suspended from the ceiling and form a barrier around the cleanroom area. | Soft-wall cleanrooms offer moderate flexibility and can be easily modified or expanded by adjusting the curtain or panel arrangements. | Soft-wall cleanrooms provide lower levels of cleanliness compared to modular or stick-built cleanrooms. They are suitable for environments where a lower level of control is required. | Soft-wall cleanrooms are generally the most cost-effective option as they involve minimal construction and use less expensive materials. |